Maximum turning diameter 450MM

Maximum processing diameter (disc type) 420MM

Maximum machining diameter (shaft type) 45MM

Maximum machining length 150MM

Maximum bar through hole diameter 45MM

stroke

X-axis effective stroke (diameter) 1000MM

Y-axis effective stroke 285MM

Z-axis effective stroke 450MM

Spindle

Spindle nose form A2-5

Maximum spindle speed 4500RPM

Spindle through hole diameter 56MM

Spindle motor power 7.5KW/11KW

Hydraulic chuck and rotary cylinder specifications 6 inches

Feed

Fast moving rate X/Y/Z 25M/MIN

X/Y/Z axis servo motor 1.3KW/1.0KW/1.3KW

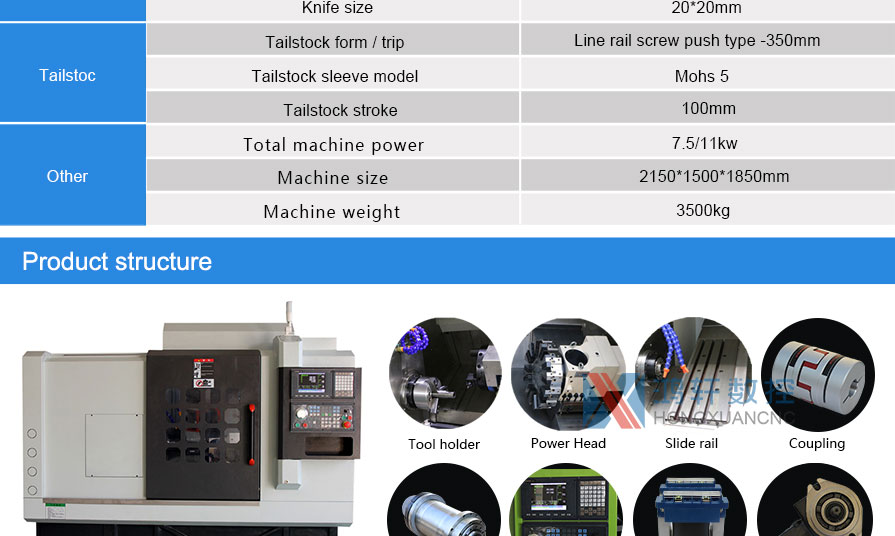

Power Head

Power head servo motor 1.8KW

Number of power heads 4+4

Power head specifications ER20

Precision

positioning accuracy ±0.005

Repeatability ±0.003

Knife tower

Turret specification Taiwan 8-station servo turret

size and weight

Dimensions 2200×1680×1900MM

weight 3400KG