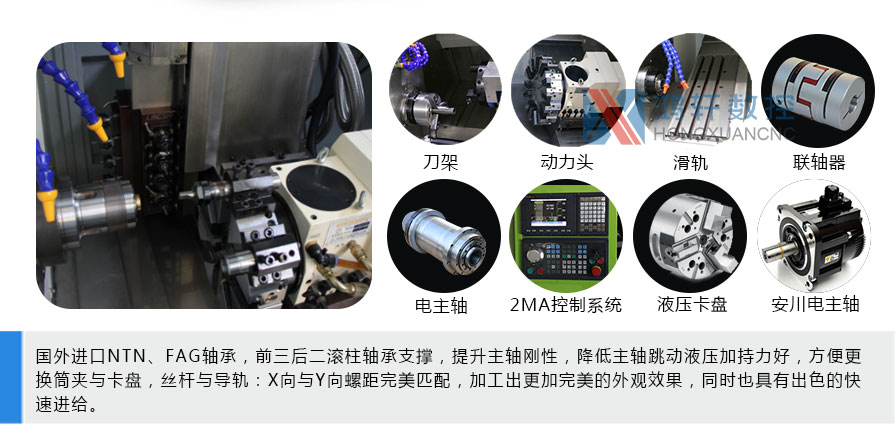

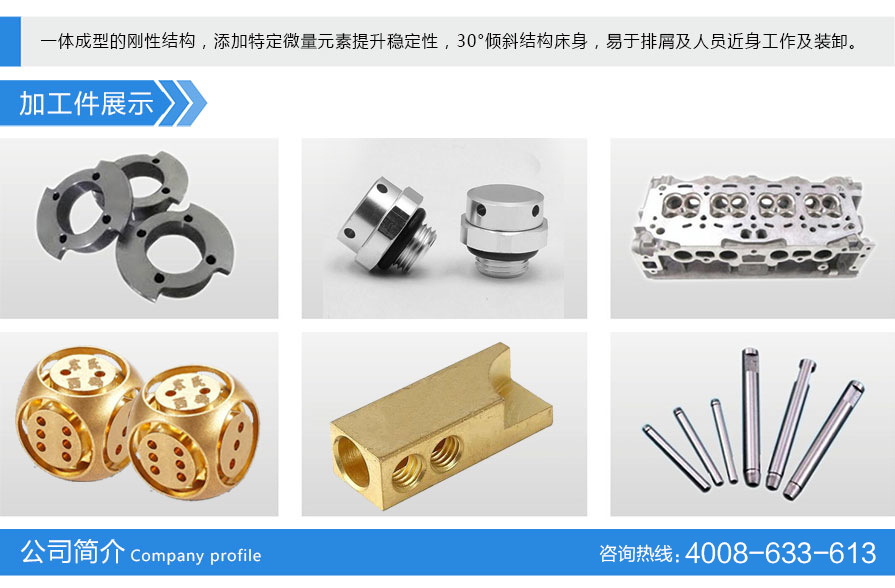

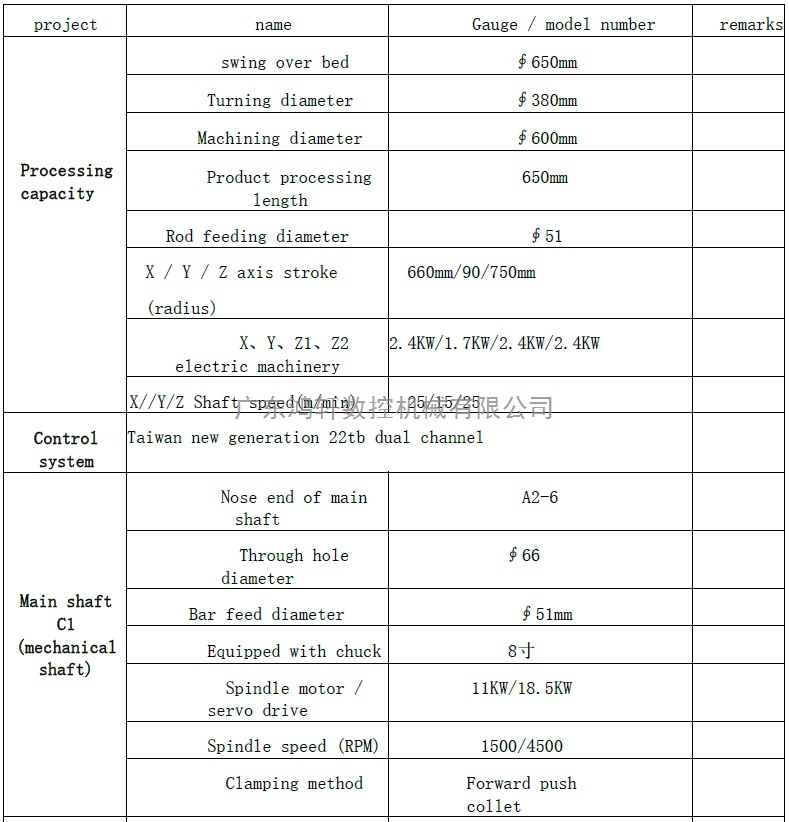

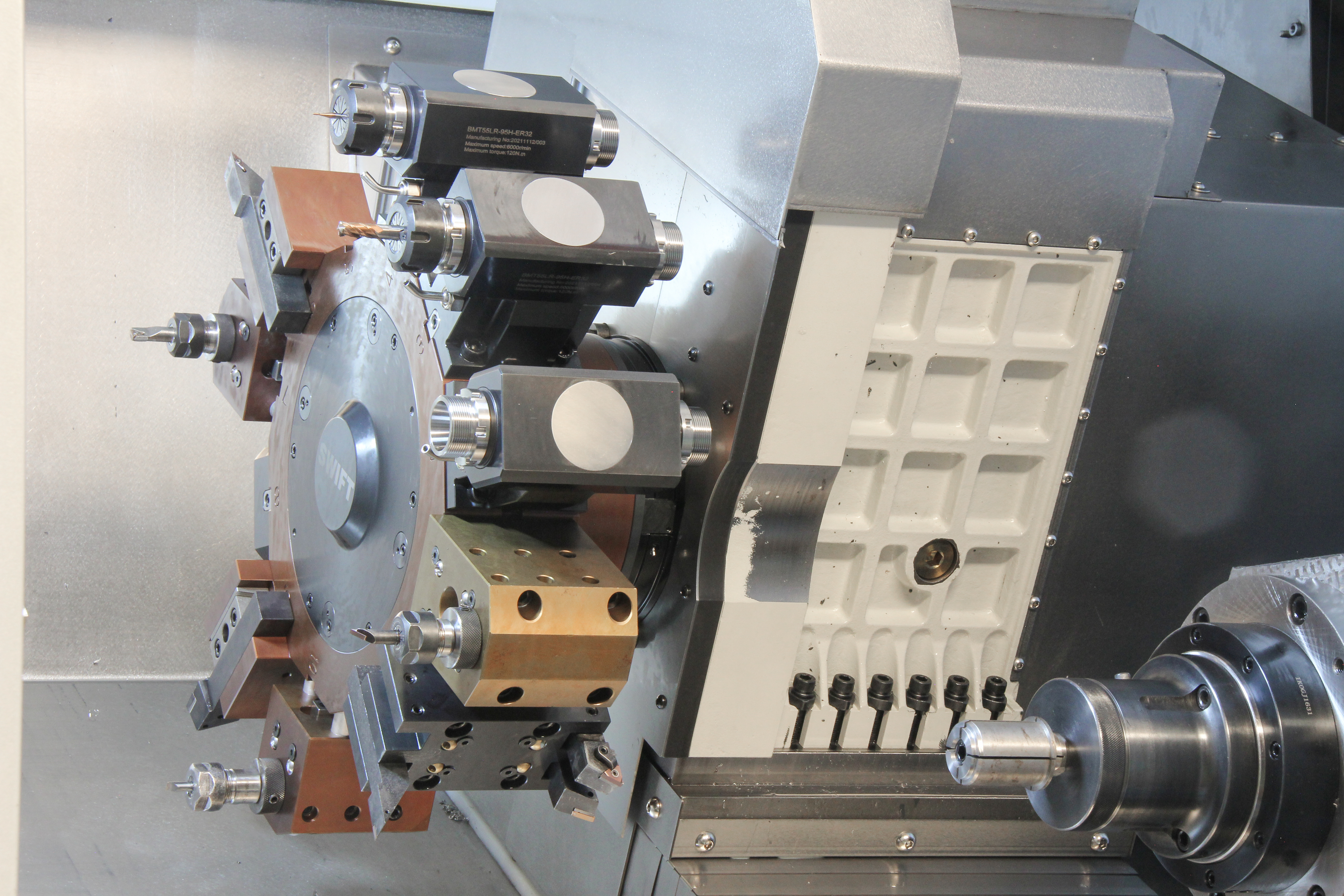

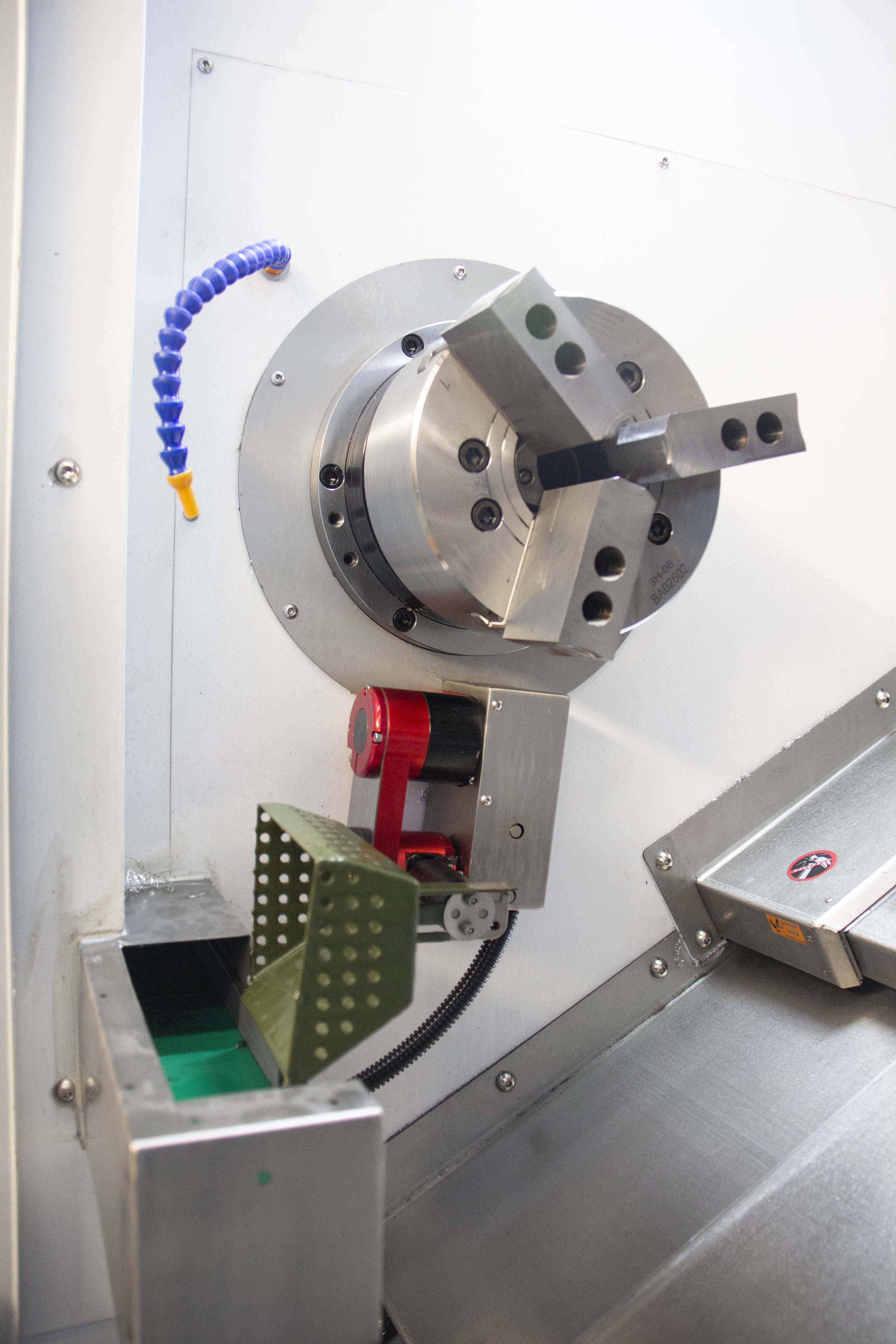

Hx-5246yt double spindle power turret machine, the first spindle a2-6, the second spindle movable A2-5, the double spindle and the 12 station power turret with y axis, is a CNC turning and milling compound lathe integrating high performance, high precision, high efficiency, high reliability, high cost performance and high safety. Its structural form is parallel and opposed arrangement of double main axes. The double spindle is controlled by the absolute coding servo motor + high-speed CNC system central multi axis linkage interpolation. It can independently write the program to move the x-axis, y-axis, Z-axis and Z1 axis, realize the automatic docking and exchange of the workpiece clamped by the main spindle and the auxiliary spindle, and work at the same time. It solves the processing problem of two processes at the clamping end of the workpiece under one clamping. It is suitable for the products that need two processes and two clamping, and realizes one clamping and two processes processing at the same time, The machine tool can realize the integration of various forms of automatic docking mechanisms, realize the advantages of small floor area and labor saving.